NONWOVEN PRODUCTION LINE AND SOLUTION

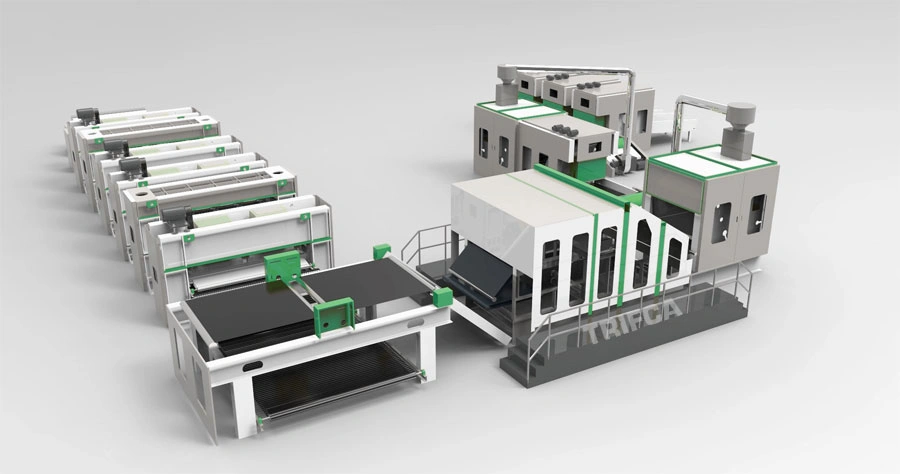

Artificial Leather Substrate Production Line - PU Nonwoven Substrate

Artificial Leather Substrate Production Line – PU Nonwoven Substrate

Artificial leather substrate production line

Application: To make synthetic leather substrate with high density PU or PVC synthetic leather substrate and polyester or sea island fine denier fiber and multi-needle tape. The products can be used in shoes, luggage, garments, furniture and other industries.

Advanced nonwoven technology solutions for Artificial Leather Substrate Production Line. Used to make PU/PVC or artificial leather substrates.

Product net width: ≤4500mm

Artificial leather substrate production line

Application: To make synthetic leather substrate with high density PU or PVC synthetic leather substrate and polyester or sea island fine denier fiber and multi-needle tape. The products can be used in shoes, luggage, garments, furniture and other industries.

Advanced nonwoven technology solutions for Artificial Leather Substrate Production Line. Used to make PU/PVC or artificial leather substrates.

Product net width: ≤4500mm

ARTIFICIAL LEATHER SUBSTRATE PRODUCTION LINE 2500MM

RAW MATERIAL

PET/ PP/

Other Fiber

APPLICATION

Synthetic leather/coverings

Automotive surfaces

Geotextiles

Roofing felts

Automotive headliners

Features and Benefits

- Rationalized workflow, efficient production

- Quick installation and easy maintenance

- Automatic operation, labor saving

- Large capacity, low losses

Özellikler & Faydalar

- Rasyonelleştirilmiş iş akışı, verimli üretim

- Hızlı kurulum ve kolay bakım

- Otomatik çalışma, iş gücü tasarrufu

- Büyük kapasite, düşük kayıplar

Equipment Features

1: Final Product Name: Synthetic Leather Substrate Production Line | Synthetic Leather Substrate Production Line

2: Raw Material: PET/PP fiber with 0.8D-3.5D 38mm–51mm

3: Finished product features: good filterability, strong protection, good flexibility, high strength. good permeability. anti-high temperature, frost resistance, aging resistance, corrosion resistance properties, etc.

4: Product Application: ARTIFICIAL LEATHER/ COATING SURFACES/ AUTOMOTIVE SURFACES/ GEOTEXTILES/ ROOFING FELTS/ AUTOMOTIVE CEILING TILES/ AUTOMOTIVE VELVET/ CARPETS (STRUCTURED AND PLAIN)/ HOMETEX/ TECHNICAL FELTS (FILTRATION)

5: Production Line Technical Parameters

_1:Machine Width: 3000mm

_2:Maximum Product Width: 2500mm

_3:Electrical control mode: Control desk or PLC | Inverter Siemens brand

6:Production Line Processing (6*punching):

Bale opener → Pre-opener → Large cabin blender → Main opener → Vibrating fiber Feeder → Double cylinder double doffer carding machine → Cross lapper → Pre-needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → Ironing → Cutting and winding machine

Nonwoven Equipment |Non-woven Production Line

Would you like to learn more about nonwoven solutions from us?

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.