NONWOVEN PRODUCTION LINE AND SOLUTION

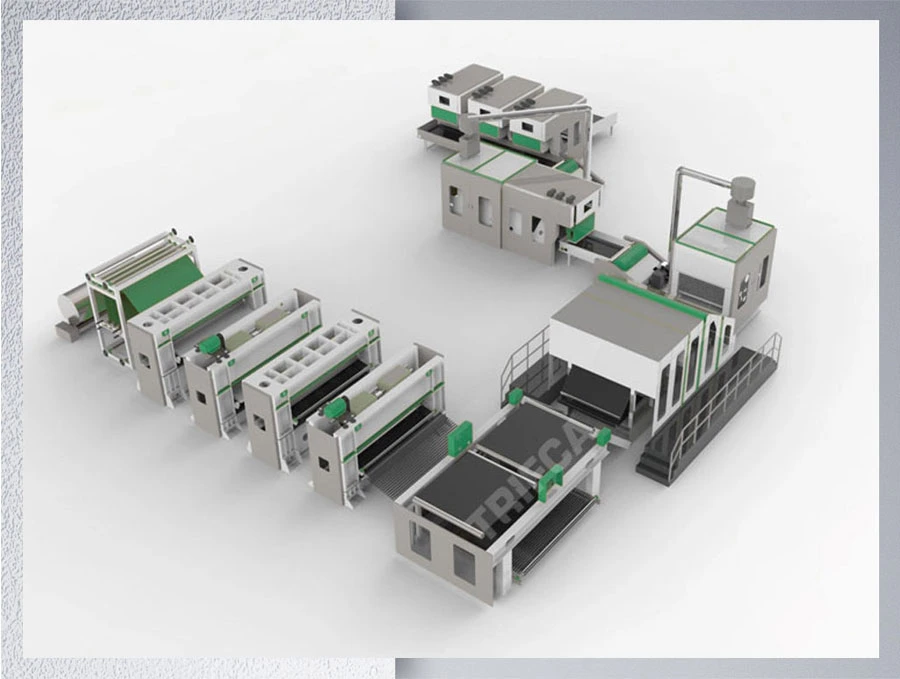

Glass Fiber Felt Production Line

Glass Fiber Felt Needle Punched Line | Nonwoven Needle Punch Makinesi

Glass Fiber Felt Production Line

Needle Punched Glass Fiber Felt Production Line

Glass fiber high temperature resistance, fireproofing, corrosion resistance, heat insulation, sound insulation, high tensile strength, good electrical insulation compared to organic fiber.

Glass fiber needle felt can be used in the automobile industry for sound insulation, sound absorption, shock absorption, flame retardant, mainly used in the industrial field of high temperature flue gas filtration: glass fiber needle felt is widely used in carbon black, steel, non-ferrous metals, chemical, incineration and other flue gas treatment industries, and dust recovery of various bag dust precipitators.

Advanced nonwoven technology solutions for glass fiber felt production line to make door panels or package trays for the automotive industry.

Needle Punched Glass Fiber Felt Production Line

Glass fiber high temperature resistance, fireproofing, corrosion resistance, heat insulation, sound insulation, high tensile strength, good electrical insulation compared to organic fiber.

Glass fiber needle felt can be used in the automobile industry for sound insulation, sound absorption, shock absorption, flame retardant, mainly used in the industrial field of high temperature flue gas filtration: glass fiber needle felt is widely used in carbon black, steel, non-ferrous metals, chemical, incineration and other flue gas treatment industries, and dust recovery of various bag dust precipitators.

Advanced nonwoven technology solutions for glass fiber felt production line to make door panels or package trays for the automotive industry.

Applications

It is used to make products by carding or air-laminating, needle-punching, heat treatment with jute and/or glass fiber blended with polypropylene.

It is shaped like door panels or package trays for the automotive industry.

Glass fiber needle felt is widely used in carbon black, steel, non-ferrous metals, chemical, combustion and other flue gas treatment industries and dust recovery of various bag dust settlers.

Features and Benefits

- Rationalized workflow, efficient production

Quick installation and easy maintenance

Automatic operation, labor saving

Large capacity, low losses

Product net width: ≤2500mm

Product specifications: ≤3000g/m²

Features and Benefits

- Rationalized workflow, efficient production

Quick installation and easy maintenance

Automatic operation, labor saving

Large capacity, low losses

Product net width: ≤2500mm

Product specifications: ≤3000g/m²

Nonwoven Equipment |Non-woven Production Line

Would you like to learn more about nonwoven solutions from us?

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.