NONWOVEN PRODUCTION LINE AND SOLUTION

Nonwoven Thermal Bonding Production Line for Padding | Furniture

Application: filling for mattress, wadding and furniture insulation.

Nonwoven Thermal Bonding Production Line for Padding | Furniture

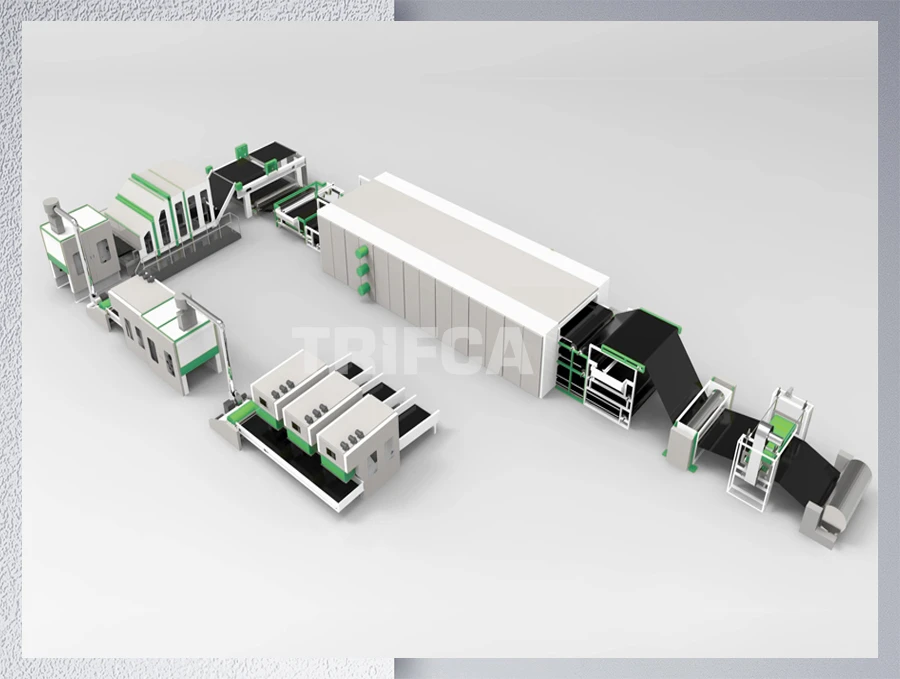

Thermal Bonding Production Line for Padding, including fiber openers, hopper feeder, carding machine, cross lapper, oven (3 layers), ironing machine and winding machine.

Trifca can produce nonwoven thermal bonding production line for padding. Application: padding for mattress, wadding and Furniture insulation.

If customer has special requirements for production width, capacity or other aspects, the production line will be customized accordingly.

Thermal Bonding Production Line for Padding, including fiber openers, hopper feeder, carding machine, cross lapper, oven (3 layers), ironing machine and winding machine.

Trifca can produce nonwoven thermal bonding production line for padding. Application: padding for mattress, wadding and Furniture insulation.

If customer has special requirements for production width, capacity or other aspects, the production line will be customized accordingly.

FURNITURE FILLER NONWOVEN THERMOBONDING LINE

RAW MATERIAL

PET/ PP/

Other Fiber

APPLICATION

Fiber Matters Filling

Mattress Padding

Soft Waddings for Furniture

Fiber Matterss Wadding

Glue-free Thermal Bonded Wadds

RAW MATERIAL

PET/ PP/

Other Fiber

APPLICATION

Fiber Matters Filling

Mattress Padding

Soft Waddings for Furniture

Fiber Matterss Wadding

Glue-free Thermal Bonded Wadds

Features and Benefits

- Rationalized workflow and efficient production

- Quick adjustment and easy maintenance

- Automatic operation with labor saving advantage

- High capacity and low waste

Applications

The product is widely used in embroidery bedding, home textile and travel products, etc. For example, pillow, sofa cushion, tatami, filter material.

This production line is especially applicable to produce soft and high loft wadding (fiber filling) products by spray bonding using synthetic fiber and chemical binder.

The product is widely used in embroidery bedding, home textile and travel products, etc. For example, pillow, sofa cushion, tatami, filter material. Furniture

Features and Benefits

- Rationalized workflow and efficient production

- Quick adjustment and easy maintenance

- Automatic operation with labor saving advantage

- High capacity and low waste

Equipment Features

1:Final Product Name: Furniture Filling Nonwoven Thermobonding Line | Upholstery Mattresses Nonwoven Thermal Bonding Production Line for Filling | Furniture

2:Raw Material:PET fiber, (5D,7D .9D hollow fiber, 4D Low melting point fiber) etc.

3:Products feature: good filterability, strong protection, good flexibility, high strength. good permeability. anti-high temperature, frost resistance, aging resistance, corrosion resistance properties etc.

4:Product Application: Suitable for the production of high-density, high-performance nonwoven fabrics such as Fiber Materials Filling/ Mattress Wadding/ Soft Wadding for Furniture/ Fiber Materials Filling/ Glueless Thermal Bonded Wadding.

5:Production Line Processing:

Bale opener → Pre-opener → Large cabinet mixer → Main opener → Vibrating fiber Feeder → Single cylinder double doffer double random carding machine → Cross lapper → oven machine → ironing → cutting and winding machineFURNITURE FILLER NONWOVEN THERMOBONDING LINE | UPHOLSTERY MATTRESSES

Nonwoven Equipment |Non-woven Production Line

Would you like to learn more about nonwoven solutions from us?

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.