NONWOVEN PRODUCTION LINE AND SOLUTION

Polyester Acoustic Panel Production Line

Acoustic Panel Nonwoven Machine

Polyester Acoustic Panel Production Line | Acoustic Panel Nonwoven Machine

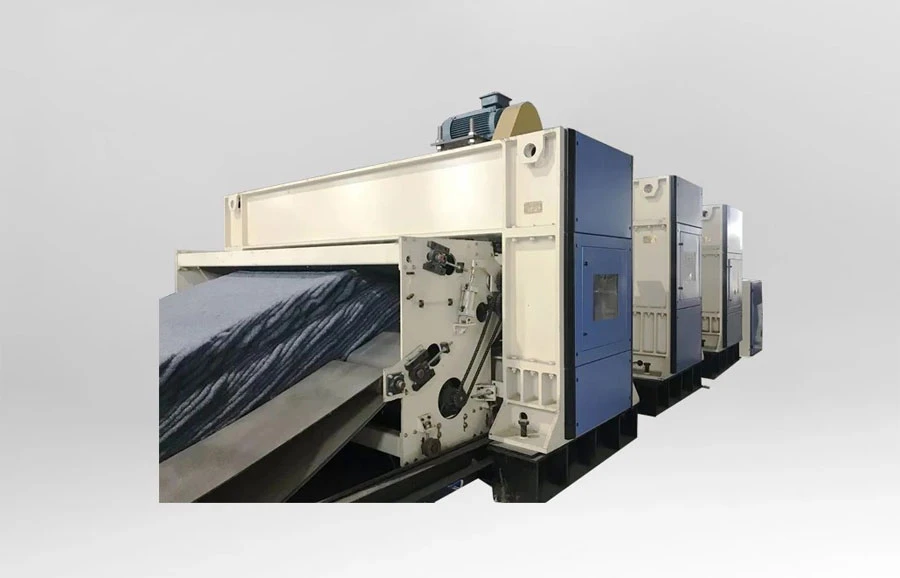

Polyester Acoustic Panel Production Line Advanced nonwoven machine solutions for acoustic fiber board, decorative fiber board for cinema, KTV building.

Combination of Needle Punching and Thermal Bonding

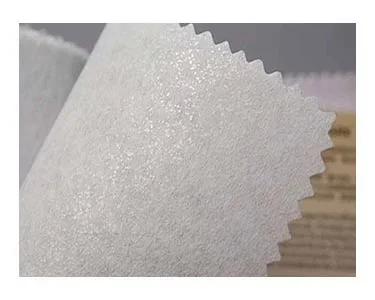

Final product: Acoustic Panel

Available raw material: polyester fiber, low melt fiber, etc.

3-inch line of high-performance acoustic panels that produce acoustic panels for interior and exterior walls, ceilings and attic acoustical treatments. Produces sound and thermal insulation that rubs tightly against wood and metal studs when installed, minimizing the transmission of sound and heat. The line can also produce acoustic insulation materials and panels of different thicknesses and compositions on request.

Polyester Acoustic Panel Production Line Advanced nonwoven machine solutions for acoustic fiber board, decorative fiber board for cinema, KTV building.

Combination of Needle Punching and Thermal Bonding

Final product: Acoustic Panel

Available raw material: polyester fiber, low melt fiber, etc.

3-inch line of high-performance acoustic panels that produce acoustic panels for interior and exterior walls, ceilings and attic acoustical treatments. Produces sound and thermal insulation that rubs tightly against wood and metal studs when installed, minimizing the transmission of sound and heat. The line can also produce acoustic insulation materials and panels of different thicknesses and compositions on request.

POLYESTER ACOUSTIC PANEL PRODUCTION LINE

RAW MATERIAL

PET/ PP/

Nylon/

Dushuk Elyafly

Vb.

APPLICATION

Acoustic Panel Acoustic Panel

Sound Absorbing Panels

Geotextile

Features and Benefits

- Combination of needle punching and thermal bonding production process

- Special configuration and optimized working process to make panel products with high hardness and density

- Up-to-date design, convenient operation thanks to PLC control, sound absorbing panels

- Cellulose Acoustic Panels, sound absorbing panels

Features and Benefits

- Combination of needle punching and thermal bonding production process

- Special configuration and optimized working process to make panel products with high hardness and density

- Up-to-date design, convenient operation thanks to PLC control, sound absorbing panels

- Cellulose Acoustic Panels, sound absorbing panels

Applications

- This production line is mainly for producing industrial used abrasive pads, such as kitchen used scouring pad and abrasive pad or coarse denier polishing pads.

Equipment Features

1:Final Product Name: Polyester Acoustic Panel Production Line Sound Absorbing Panels Making Machine | Acoustic Panel Production Line Acoustic Panel Production Line

2:Raw Material:PET fiber, polyester, nylon, low staple fiber, etc.

3:Features of finished product coming out of the production line:

Strong filtration, strong protection, good flexibility, high strength, good air permeability, sound insulation, heat insulation/high temperature resistance, frost resistance, aging resistance, corrosion resistance, wear resistance and other properties.

4:Product Application:Suitable for the production of high-density, high-performance nonwovens for Acoustic Panel, Sound Absorbing Panels and Sound Insulation panels.

It can also be adapted for the production of fiber material fillings/bed fillings/geotextile/carpet, etc.

5:Production Line Processing:

Bale opener → Pre-opener → Large cabin blender → Main opener → Vibrating fiber Feeder → Double cylinder double doffer carding machine → Cross lapper → Pre-needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → Ironing → Cutting and winding machine

Nonwoven scouring pads for cleaning the production line of scouring pads for making kitchen scouring pads, industrial abrasive pads and polishing pads

Nonwoven scouring pads for cleaning the production line of scouring pads for making kitchen scouring pads, industrial abrasive pads and polishing pads

Nonwoven Equipment |Non-woven Production Line

Would you like to learn more about nonwoven solutions from us?

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.