NONWOVEN PRODUCTION LINE AND SOLUTION

Waste Fiber Felt Nonwoven Production Line

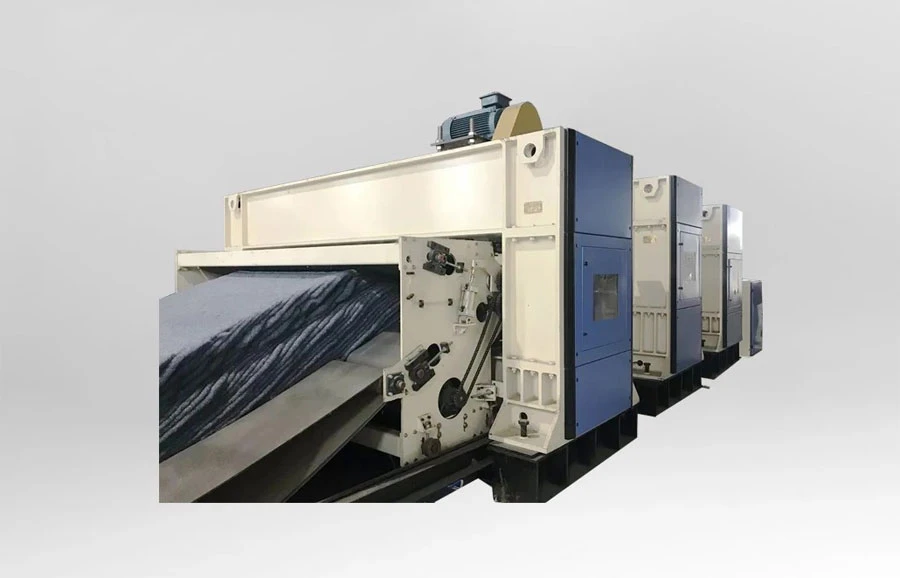

Needle Punching- Waste Fiber Felt Nonwoven Production Line

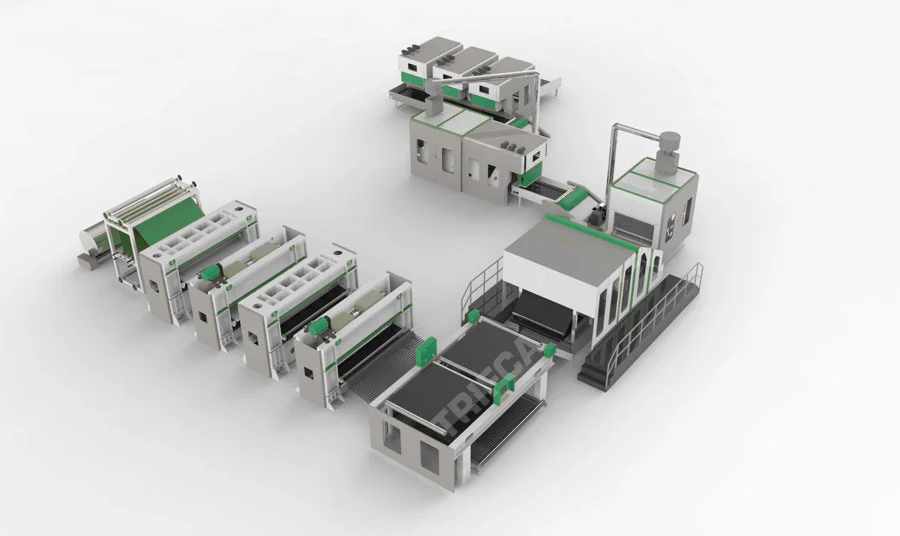

1. Waste felt needle punching fabric production line

Advanced Needle Punching nonwoven solutions for waste felt production line, to make fiber felt with waste recycled fiber or low melt fiber.

2. Raw Material: Polyester staple fiber, polyester hollow staple fiber

fiber (optional), Low melting point fiber and natural wool fiber etc, specification: 2.5d~15d

3. Production process: Polyester staple fiber, hollow staple polyester (waste fiber or waste fabric fiber) and a percentage of low melting point fibers are opened and mixed by opener, then carded and overlapped to the desired thickness and adjusted by needle, oven and setting process.

Waste felt needle punching fabric production line. Recycling And Reuse Of Carpet Fibers After Consumption

Advanced Needle Punching nonwoven solutions for waste felt production line, to make fiber felt with waste recycled fiber or low melt fiber.

2. Raw Material: Polyester staple fiber, polyester hollow staple fiber

fiber (optional), Low melting point fiber and natural wool fiber etc, specification: 2.5d~15d

3. Production process: Polyester staple fiber, hollow staple polyester (waste fiber or waste fabric fiber) and a percentage of low melting point fibers are opened and mixed by opener, then carded and overlapped to the desired thickness and adjusted by needle, oven and setting process.

Production Line Processing

Bale Opener → pre-opener → main opener → Vibratory Feeder → Single Cylinder double doff Carding Machine → Cross Lapper → pre-needle punching → down bench medium speed needle punching → up bench medium speed needle punching → iron machine → Automatic Tilter and Wrapper

RECYCLING AND REUSE OF CARPET FIBERS AFTER CONSUMPTION

RAW MATERIAL

Polyester staple fiber, polyester

hollow staple fiber(optional),

Low melting point

fiber and natural wool fiber etc.,

APPLICATION

Recycled carpet,

recycled

eco-friendly mats

Features and Benefits

- Heavy duty needle punching machines.

- Making high density and thickness products (over 1500GSM).

- Additional cleaner and filtering system to keep the environment clean.

- Designed especially for low quality fiber raw material and high capacity production.

Features and Benefits

- Heavy duty needle punching machines.

- Making high density and thickness products (over 1500GSM).

- Additional cleaner and filtering system to keep the environment clean.

- Designed especially for low quality fiber raw material and high capacity production.

Equipment Features

1: Final Product Name: Waste Fiber Felt Nonwoven Production Line.

2: Raw Material:Olyester staple fiber, polyester hollow staple fiber (waste fiber or waste fabric fiber, optional),Low melting point fiber and natural wool fiber etc.

3: The feature of products: good filterability, strong protection, good flexibility, high strength. good permeability. anti-high temperature, frost resistance, aging resistance, corrosion resistance properties etc.

4: Product Application: 1. Products Application: The product is widely used in industry, packaging, automotive

5:Production Line Processing:

Bale Opener → pre-opener → main opener → Vibrating Feeder → Single Cylinder double doff Carding Machine → Cross Lapper → pre-needle punching → down bench medium speed needle punching → up bench medium speed needle punching → iron machine → Automatic Slitter and Winder

Recycling Reuse Post Consumer Carpet Nonwoven Recycling of post-consumer carpet fibers Needle punching nonwoven solutions for waste felt production line to make fiber felt with waste recycled fiber or low melt fiber.

Recycling Reuse Post Consumer Carpet Nonwoven Recycling of post-consumer carpet fibers Needle punching nonwoven solutions for waste felt production line to make fiber felt with waste recycled fiber or low melt fiber.

Nonwoven Equipment |Non-woven Production Line

Would you like to learn more about nonwoven solutions from us?

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.