NONWOVEN PRODUCTION LINE AND SOLUTION

Nonwoven Sound Insulation Material Machine

Acoustic Panel Nonwoven Machine

Nonwoven Sound Insulation Material Machine | Acoustic Production Line Nonwoven Machine

Advanced non-woven mechanical solution for non-woven sound insulation material sound absorption board.

Needle punching and thermal bonding combination

Latest products: sound-absorbing board/sound-absorbing board/sound-insulating material

Available raw materials: polyester fiber, low melt fiber, etc.

A series of 3-inch high-performance sound insulation panels, producing sound insulation panels for internal and external walls, ceilings and attics. After installation, it closely rubs against wood and metal studs, producing sound insulation and heat insulation, and minimizing the spread of sound and heat. The production line can also produce sound insulation materials and sound insulation boards with different thicknesses and compositions according to user requirements.

Advanced non-woven mechanical solution for non-woven sound insulation material sound absorption board.

Needle punching and thermal bonding combination

Latest products: sound-absorbing board/sound-absorbing board/sound-insulating material

Available raw materials: polyester fiber, low melt fiber, etc.

A series of 3-inch high-performance sound insulation panels, producing sound insulation panels for internal and external walls, ceilings and attics. After installation, it closely rubs against wood and metal studs, producing sound insulation and heat insulation, and minimizing the spread of sound and heat. The production line can also produce sound insulation materials and sound insulation boards with different thicknesses and compositions according to user requirements.

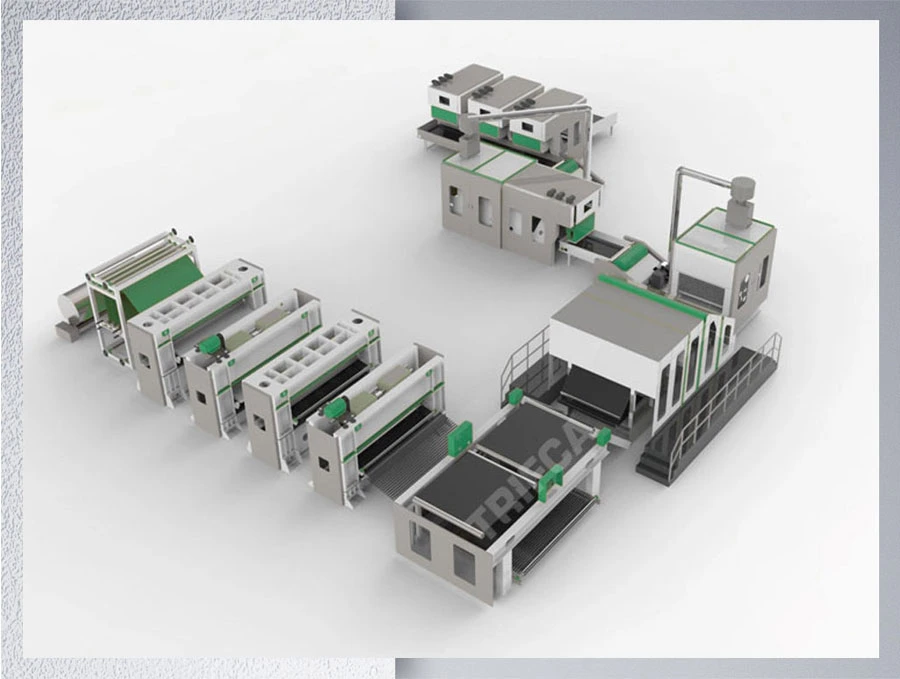

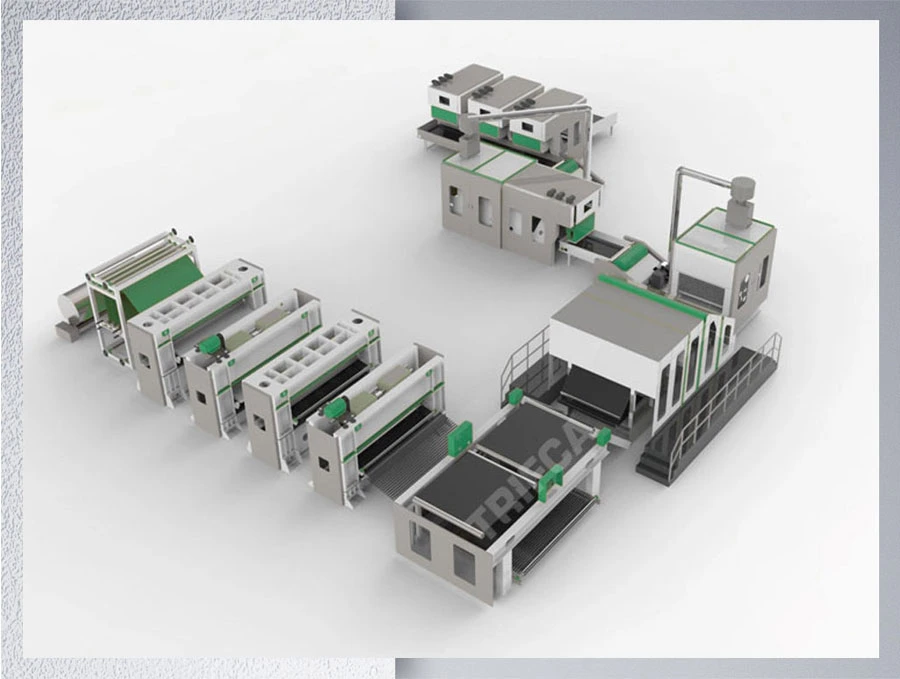

NONWOVEN SOUND INSULATION MATERIAL ACOUSTIC PANEL PRODUCTION LINE

RAW MATERIAL

PET/ PP/

Nylon/

Low Fiber

Etc.

APPLICATION

Acoustic Panel Acoustic Panel

Sound Absorbing Panels

Geotextile

- The dependence of textile factories on foreign countries has been reduced through the introduction of air conditioning, dust and waste collection systems.

- Today, Tüfekçi Makine has become a pioneer company in the Turkish and world markets by establishing and supplying the most important air conditioning, dust and waste collection project systems for textile, packaging, food and many other industries.

- We do not only deal with yarn, but also with various branches of textile such as woven or non-woven fabric production, carpet manufacturing and technical textile manufacturing, as well as other areas of the industry that I have just mentioned”

- Tekstil News : What sets you apart from your competitors in your industry in the national and international markets? Why should your customers choose you over others?

- Seguin Yildirimdemir; “Due to our energy efficiency, the automation we use in our systems is of our own design, which is not the case with any of our competitor companies (including our foreign competitors) and offers our customers great benefits in terms of energy efficiency. In addition, we are always one step ahead of our competitors in terms of customer satisfaction, thanks to the quick solutions we offer our customers in a competitive environment and the fact that they know and see that we are with them from the initial stages to the commissioning phase of their project, even after encountering problems. In addition, by re-learning the understanding of the business to approach every project we encounter, each one correctly designed and calculated, we work with our valued team, with whom we share the same ethos to ensure that the product is produced and delivered in a way that enables our customers to create added value and thus benefit from co-benefits. So wherever we go

- “If the Tüfekçi machine arrives, the problem is solved.” In this way, we transform our customers’ investments into systems they can use with confidence, and we create a visionary alliance to ensure the sustainability of these systems as impactful and preferred investments.

Features & Benefits

- Combined needle punching and thermal bonding production process

Special configuration and optimized working process to make panel products with high stiffness and density - Up-to-date design, convenient operation thanks to PLC control, sound-absorbing panels

.Cellulose Acoustic Panels, sound absorbing panelsd

Features & Benefits

- Rationalized workflow, efficient production

- Fast installation and easy maintenance

- Automatic operation, labor saving.

- Large capacity, low losses

Applications

- This production line is mainly for producing industrial used abrasive pads, such as kitchen used scouring pad and abrasive pad or coarse denier polishing pads.

Equipment Specifications

1: Final Product Name: Nonwoven Sound Insulation Production Line Nonwoven Sound Insulation Material Production Line

2: Raw material:PET fiber, polyester, nylon, low staple fiber etc.

3: Characteristics of the finished product coming out of the production line:

Strong filtering, strong protection, good flexibility, high strength, good air permeability, sound insulation, heat insulation/high temperature resistance, frost resistance, aging resistance, corrosion resistance, wear resistance and other properties.

4: Product Application: Suitable for the production of high density, high performance nonwovens for Acoustic Panel, Sound Absorbing Panels and Sound Insulation panels.

It can also be adapted for the production of fiber material fillers/bedding fillers/geotextile/carpet etc.

5:Production Line Processing:

Bale opener → Pre-opener → Big cabin blender → Main opener → Vibrating fiber Feeder → Double roller double doffer carding machine → Cross lapper → Pre-needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → Ironing → Cutting and winding machine

Acoustic Panel Production Line Nonwoven Sound Insulation nonwoven machine Acoustic Panel fiber sheet

Advanced nonwoven machine solutions for Ses Yalıtım Malzemesi Absorbing Panels Acoustic fiber board, decorative fiber board for cinema, KTV building.

Nonwoven Equipment|Non-woven Production Line

Would you like to learn more about nonwoven solutions from us?

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.

Contact us

Uzmanlarımız fikirlerinizi ve ihtiyaçlarınızı dinlemekten mutluluk duyacaktır,

Non-woven çözümleri söz konusu olduğunda.