NONWOVEN PRODUCTION LINE AND SOLUTION

PET Sound Absorbing Panels Sound Absorbing Panels Production Line

Acoustic Panel Nonwoven Machine

PET Sound Absorbing Panels Sound Absorbing Panels Production Line

Advanced nonwoven machine solutions for PET Sound Absorbing Panels acoustic fiber sheet, decorative fiber sheet for cinema KTV building. Sound absorbing panels.

A range of 3 inch high performance acoustic panels producing acoustic panels for interior and exterior walls, ceilings and attic acoustic treatments. When installed, they rub tightly against wood and metal studs, producing sound and thermal insulation that minimizes sound and heat transmission. The line can also produce acoustic insulation materials and panels in different thicknesses and compositions upon request.

Advanced nonwoven machine solutions for PET Sound Absorbing Panels acoustic fiber sheet, decorative fiber sheet for cinema KTV building. Sound absorbing panels.

A range of 3 inch high performance acoustic panels producing acoustic panels for interior and exterior walls, ceilings and attic acoustic treatments. When installed, they rub tightly against wood and metal studs, producing sound and thermal insulation that minimizes sound and heat transmission. The line can also produce acoustic insulation materials and panels in different thicknesses and compositions upon request.

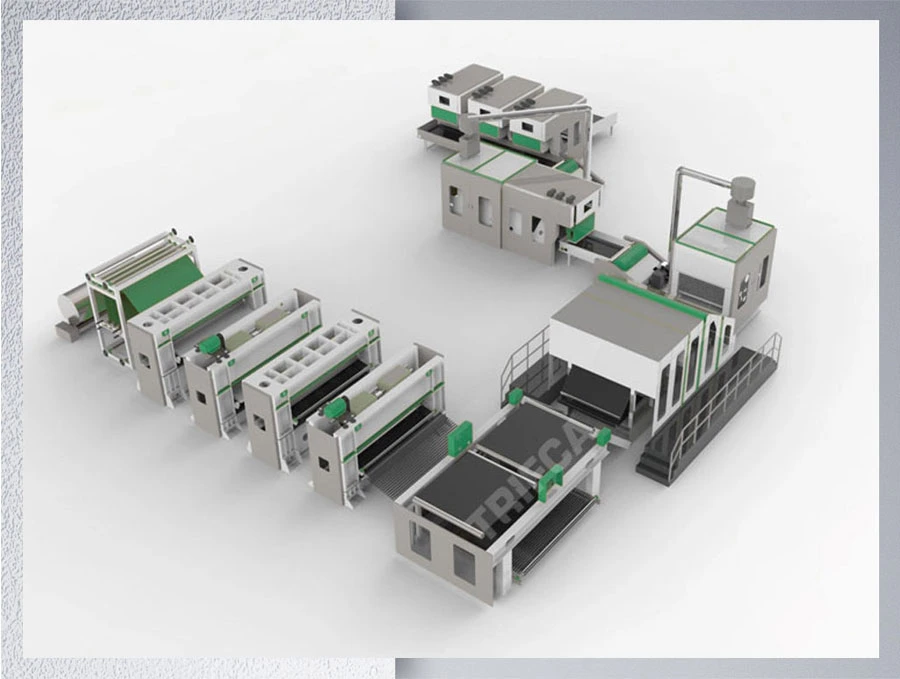

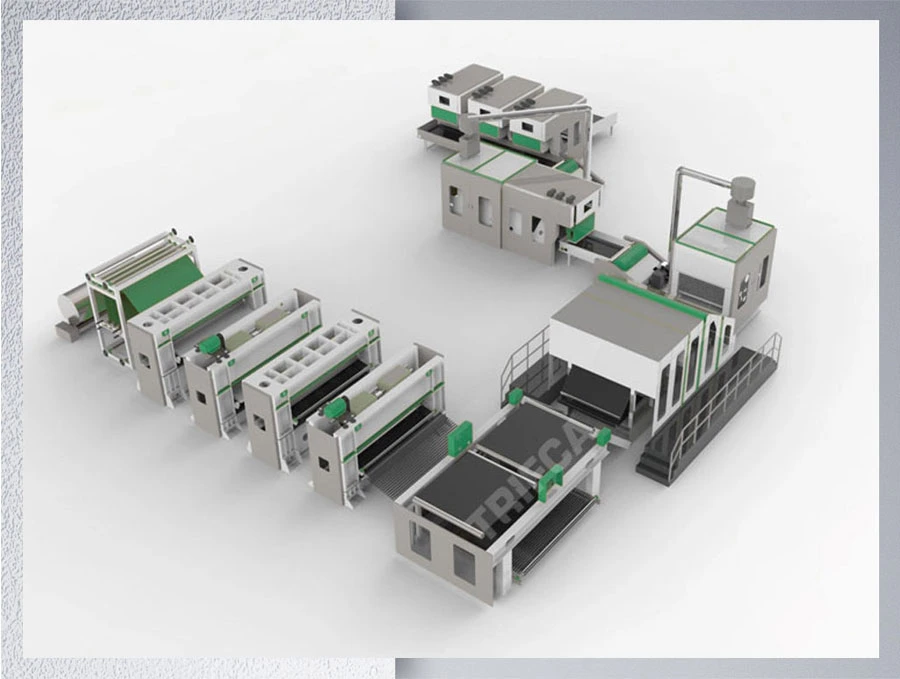

PET ACOUSTIC PANEL PRODUCTION LINE SOUND ABSORBING PANELS MAKING MACHINE

RAW MATERIAL

PET/ PP/

Nylon/

Low Fiber

Etc.

APPLICATION

Acoustic Panel Acoustic Panel

Sound Absorbing Panels

Geotextile

Sound Absorbing Panels

Tekstil News: Are your products domestic? Or are they based on imported systems?All of our products, with the exception of those used in the system for communication and electronic components, which are produced in order to reduce the dependence of our textile mills (one of the leading sectors of the country’s economy) on foreign countries, are produced exclusively with domestic raw materials. In other words, as Tüfekçi Makine, every machine we make with human labor is domestic and national.

Tekstil News: Can you tell us about your marketing and sales strategy? Have you set target countries/regions?

Our biggest sales strategy is the trust our customers place in us. By combining trust in us with quality and technology to achieve sustainable production; offering innovative technology, solution-oriented products and projects is our basic sales strategy. Our main goal is to continue to see Tüfekçi mechanical systems in all countries of the world where the textile industry is growing and developing.

Tekstil News: Can you tell us about your innovations and the new projects you want to realize?

As Tüfekçi Makine, the inputs we provide should include smart technology, which is very important for textile mills. By using smarter air conditioning, dust and waste collection systems, we are installing systems to support increased machine turnover and production capacity. In order for our customers to increase the efficiency of their employees and machines, we need to create more comfortable breathing environments for both machines and employees in the work environment, and through these efforts, machines can work more efficiently and we can utilize manpower more effectively.

In this regard, in order to improve the efficiency of our clients’ employees and machines, we are constantly striving to keep track of the latest technological innovations and integrate them into our systems using various smart technologies and even artificial intelligence. We know that this is the age of digitization, and we work with our customers to guide our R&D within this framework in order to utilize manpower more efficiently.

Tekstil News: Have you participated in international exhibitions before? If you have, have you found them useful?Of course, I have found trade shows to be very useful. Because trade shows bring the industry together and meet the needs of customers; provide direct access in a short period of time and in the most efficient way, thus enabling companies to make significant gains in sales and promotions and to mediate one-to-one marketing of their products, systems and works to participants. In order to get in touch with the industry and increase our market relations, we participate in CAITME Uzbekistan, which has been held annually since 2008 and biennially since this year, and we plan to take part in such a platform this year!

Features & Benefits

- Combined needle punching and thermal bonding production process

- Special configuration and optimized working process to make panel products with high stiffness and density

- Up-to-date design, convenient operation thanks to PLC control, sound-absorbing panels

- Cellulose Acoustic Panels, sound absorbing panels

Features & Benefits

- Combined needle punching and thermal bonding production process

- Special configuration and optimized working process to make panel products with high stiffness and density

- Up-to-date design, convenient operation thanks to PLC control, sound-absorbing panels

- Cellulose Acoustic Panels, sound absorbing panels

Applications

- This production line is mainly for producing industrial used abrasive pads, such as kitchen used scouring pad and abrasive pad or coarse denier polishing pads.

Equipment Specifications

1: Final Product Name: Polyester Acoustic Panel Production Line Sound Absorbing Panels Making Machine | Acoustic Panel Production Line Acoustic Panel Production Line

2: Raw material:PET fiber, polyester, nylon, low staple fiber etc.

3: Characteristics of the finished product coming out of the production line:

Strong filtering, strong protection, good flexibility, high strength, good air permeability, sound insulation, heat insulation/high temperature resistance, frost resistance, aging resistance, corrosion resistance, wear resistance and other properties.

4: Product Application: Suitable for the production of high density, high performance nonwovens for Acoustic Panel, Sound Absorbing Panels and Sound Insulation panels.

It can also be adapted for the production of fiber material fillers/bedding fillers/geotextile/carpet etc.

5:Production Line Processing:

Bale opener → Pre-opener → Big cabin blender → Main opener → Vibrating fiber Feeder → Double roller double doffer carding machine → Cross lapper → Pre-needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → High speed main needle punching machine → Ironing → Cutting and winding machine

Nonwoven Ses Yalıtım Malzemesi Makinası Akustik Panel Üretim Hattı Acoustic Panel Ses Emici Sound Absorbing Panels

Nonwoven Equipment|Non-woven Production Line

Would you like to learn more about nonwoven solutions from us?

Contact us

Our experts will be happy to listen to your ideas and needs,

When it comes to non-woven solutions.

Contact us

Uzmanlarımız fikirlerinizi ve ihtiyaçlarınızı dinlemekten mutluluk duyacaktır,

Non-woven çözümleri söz konusu olduğunda.